The cast metal process is extensive. There are many different steps to the process. Below are pictures of the modern cast metal mold-making process, illustrating how I made Palm (2014).

First we start with the "pattern." The pattern is the object that is desired in metal. Whatever the object looks like, the finished casting will look like. Here, I have a piece of palm tree bark with added wax texture. We laid the pattern down and built wooden walls, called a "flask," around the pattern.

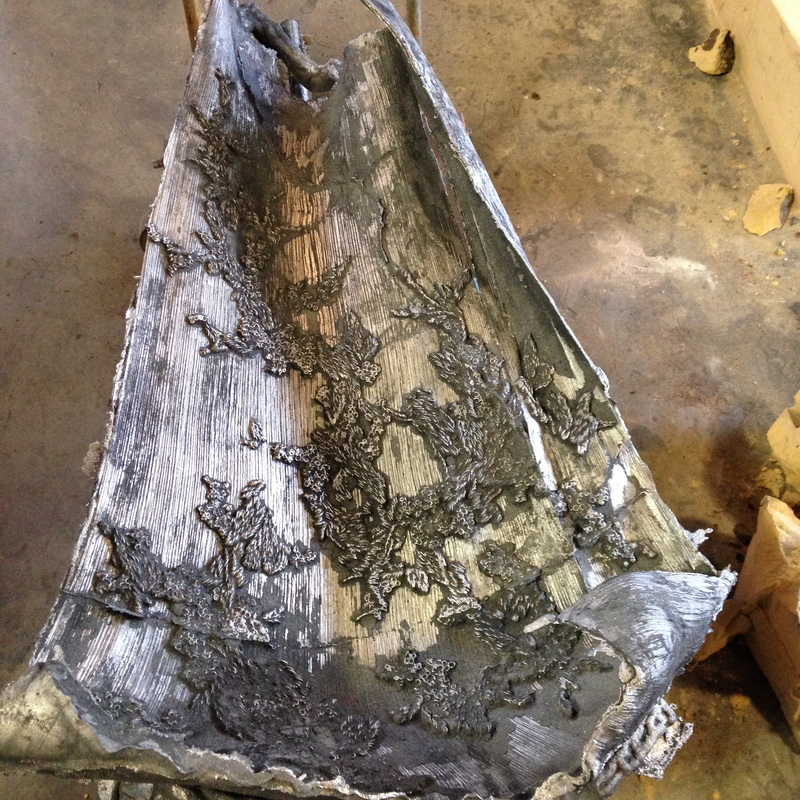

Here we see the beginning of the sand mold. Since the piece of palm tree bark curled over itself, multiple parts were needed to complete the mold. Here are the first two parts of the mold.

Each piece of the mold is made with a resin-bonded sand. In a large mixer, the three-part resin and the sand are mixed together. Once completely mixed, we take the sand out of the mixer and push it up against the pattern. This process is called "ramming." Ramming must be done firmly to make sure the pattern leaves an impression in the sand. The resin sand sets up over time until it is extremely hard.

It is now time to add the "gating system." The gating system is the combination of channels that connect together, forming a pathway for the metal to flow into the pattern.

In this instance, I used pipes to create most of the gating system. On smaller pieces these can be added later by drilling into the mold halves once they are set up. I also have another inner metal structure propped up in the mold.

Next the pattern needs to be covered in a solution called "mold wash." Mold wash is a mixture of powdered graphite and denatured alcohol. We add this to the pattern to prevent "burn in," or when the sand sticks to the metal casting, creating an ugly sand texture on the surface of the piece.

The small particles of graphite in the mold wash fill the gaps left between particles of sand, ensuring a smoother surface.